Carbon dioxide (CO2) captured via Direct Air Capture (DAC) has been permanently stored in concrete for the first time ever.

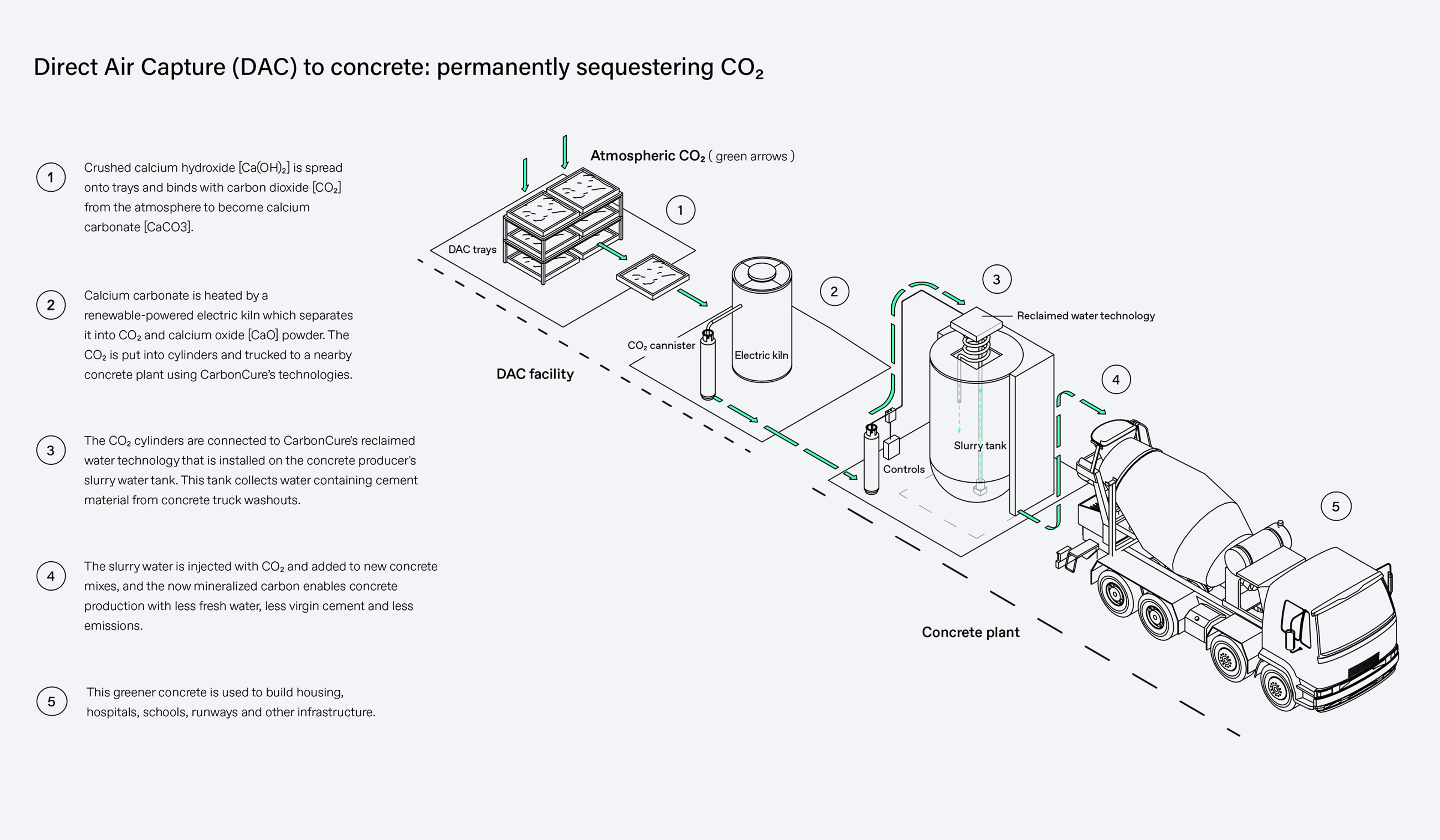

Heirloom captured CO2 from the atmosphere using their DAC technology at their headquarters in Brisbane, California. CarbonCure's Reclaimed Water Technology injected the captured CO2 into recycled water at a Central Concrete batch plant in San Jose, California. Central Concrete used the CO2-treated water to make fresh concrete, which was used across projects in the Bay Area. The CO2 is permanently sequestered in the concrete as calcium carbonate, and will not be returned to the atmosphere for centuries, even if the concrete is demolished.

Heirloom runs America’s only operational DAC facility. It uses limestone, an abundant, easy-to-source and inexpensive material, to pull CO2 from the air. Harnessing a cyclic process, the limestone is broken down into calcium oxide rock and CO2 gas using heat from a renewable-energy powered, electric kiln. The calcium oxide is spread onto vertically stacked trays where it acts like a sponge - pulling CO2 from the air before it is returned to the kiln and the process begins again. The captured CO2 gas is then permanently stored safely underground – or as was the case with this milestone – embedded in concrete.

The global leader in permanent carbon storage in concrete, CarbonCure Technologies manufactures a suite of carbon mineralization solutions for the concrete industry. CarbonCure’s Reclaimed Water Technology was used to store Heirloom’s CO2 at Central Concrete. The technology injects CO2 into reclaimed water (recycled water collected from washing out concrete trucks) at concrete plants. When injected, the CO2 immediately reacts with cement in the water and mineralizes, permanently storing the CO2 and stabilizing the cement for reuse. The CO2-treated slurry is then used in new concrete mixes.

Central Concrete’s role in this milestone DAC-to-Concrete demonstration project reflects their continued position as a concrete industry leader in designing, testing and delivering higher-performing concrete while significantly reducing the carbon footprint of construction projects. Central Concrete was the first concrete supplier in the Bay Area to adopt CarbonCure’s technologies for ready-mixed concrete, and continually offers innovative solutions for building and infrastructure projects. Their technical team focuses on cutting-edge research, quality assurance and sustainability considerations to provide solutions that match material performance requirements, environmental standards and constructability needs for the built environment.

“This demonstration project is a global milestone for carbon removal technology that confirms concrete’s enormous potential as a climate solution that can permanently store carbon in our most essential infrastructure – from roads and runways to hospitals and housing,” said Robert Niven, Chair and CEO of CarbonCure Technologies. “We’re thrilled to be collaborating with Heirloom and Central Concrete on this groundbreaking world first.”

“The science is clear: in order to reach climate goals we must remove billions of tons of already emitted CO2 from the atmosphere each year,” said Shashank Samala, CEO of Heirloom. “This is an important step toward that future and shows the promise of DAC technologies combined with smart, permanent methods of sequestration.”

This application of a DAC-to-concrete solution is a significant step forward in permanent atmospheric CO2 removal. As the world moves toward zero-carbon energy generation, DAC technologies will play a key role in remediating past emissions, and helping to decarbonize industries as they develop and scale carbon-cutting solutions.

Even the most aggressive emissions reduction projections from the UN Intergovernmental Panel on Climate Change will require the removal of 6-10 billion tons of CO2 per year by 2050 to stick to a 1.5˚C warming pathway. DAC technologies are some of the most promising methods of carbon dioxide removal, and have recently received large investments from the U.S. government through the Department of Energy’s $3.5 billion DAC hub program and the Inflation Reduction Act.

The world’s most-utilized building material, concrete provides an important repository for permanent CO2 storage. With the global building stock expected to double by 2060 - the equivalent of building another New York City every month - concrete presents a key opportunity to store immense quantities of carbon dioxide in our built environment.